WhatsApp: +86-15652116876 E-mail: jcx@jcxcnc.com Tel: +86-1065568853

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The stone bridge cutting machine is a popular product among kitchen and bathroom stone manufacturers. It is specially designed for cabinet artificial stone, quartz, granite, marble, tile, glass, wood, etc. It saves time and effort and is specially designed for kitchen and bathroom stone production.

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

JCXstone-4Z+1

JCXstone

4+1 Axis Bridge Cutting Machine

Machine Feature :

This machine is made of heavy materials, with a solid bed, which is durable and does not deform. The whole machine is processed by a large five-sided milling machine for guide rail surface and drilling. The key parts of the machine are imported high-quality accessories, with high processing precision, large production capacity and higher degree of automation. It adopts imported high-precision ball screw transmission, and the screw is highly heat-treated. The wear resistance is more durable and the service life of the whole machine is extended. This equipment has high-end configuration, the machine adopts servo control, fast running speed and stable operation. Intelligent and automated advantages:

1. The equipment adopts 15KW high-power special cutting motor, copper core coil, ultra-high power, low speed and high torque, high cutting force, and more labor-saving cutting. The machine adopts servo drive motor, stable processing, low noise and low heat. The cutting speed fluctuates up and down according to the hardness of the cutting material, processing speed and cutting depth.

2. The genuine four-axis control system with a movable handle is flexible for point positioning, easy to learn and use, while ensuring the accuracy of the equipment and high cost performance. The machine head can swing 360 degrees at will, and can cut the plate at any angle and any shape: horizontal cutting, vertical cutting, arc cutting, elliptical cutting, and circular cutting. The saw blade motor is added, and the machine head can automatically mill the cutter after being vertical, and can open the inner corner.

3. The system is highly user-friendly and has extremely low educational requirements. The machine can be operated at the elementary school level. It can directly recognize CAD and directly modify the size according to customer requirements in the operation program for cutting and processing, without using complex programs to produce CNC paths. The manufacturer provides free training on machine use.

4. Different from the three-axis stone cutting machine, this machine can not only cut and shape, but also cut large plates, perform 45-degree chamfers, open basin holes, stove holes, and cut oblique lines. Infrared positioning, precise cutting, and reduced waste generation.

5. The important electrical components in the control cabinet are all well-known brands, with strong impact resistance, anti-interference, moisture resistance and stability. The whole machine is resistant to strong electromagnetic interference, stable and reliable, ensuring long-term stable processing and operation of the equipment, and the chassis has a power-off protection function. The whole machine is waterproof to reduce water splashing, and the waterproof and dustproof structure effectively prevents dust or water from corroding the guide rails and screws, thereby increasing the life of the machine tool.

6. The new drag chain is used to separate the signal line and the power line according to the specifications, which can better prevent signal interference. The internal partition of the drag chain is fixed to prevent the cables from being twisted together during operation. The cable line adopts imported high-flexibility shielded wire, which has a longer service life.

7. The platform flips 85 degrees, and it is convenient and labor-saving to load and unload large heavy boards. The new five-axis saw has added functions, which does not require manual movement of the cut boards, and the tables of different customers can automatically optimize the layout, saving materials. One-time splicing and cutting. In short, the function upgrade has added the functions of automatic board movement and automatic optimization of layout.

8. The C-axis of the machine adopts a hollow subtraction machine, which has higher processing accuracy when used.

9. The attached machine head adopts a professional stone-specific spindle with a revolution of 24,000 and strong cutting force.

Application Industry :

1. Decoration industry : special-shaped lines and relief carvings on stone background walls;

2. Stone countertops for basin holes and European-style edging : suitable for artificial stone cabinets, quartz, granite, marble countertops and washbasins, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, rear arc water forming and polishing, etc.

3. 0 and 45-degree side cutting.

4. Drilling, grinding, trimming, carving, cutting, polishing and carving of other special-shaped stones, ceramics, glass, and ceramic stones.

Applicable Materials :

The stone bridge cutting machine is a popular product among kitchen and bathroom stone manufacturers. It is specially designed for cabinet artificial stone, quartz, granite, marble, tile, glass, wood, etc. It saves time and effort and is specially designed for kitchen and bathroom stone production.

Standard Requirements :

1. Mechanical safety standards, in line with national safety standards and national health regulations.

2. The equipment has good and comprehensive safety protection measures.

3. Movable parts that are frequently adjusted and maintained.

4. Electrical safety standards, the control system can ensure that there will be no danger when the equipment is powered off, and the equipment itself and personnel will not be harmed.

5. The electrical control system of the equipment has overload protection and short circuit protection functions

Technical Parameter :

Working size | Three-axis | 3200*2000*400mm |

C-axis | ±360° | |

A-axis | 0 and 45° | |

Saw Blade Diameter | 350mm-400mm | |

Bed frame | Seamless welding , Aging treatment, Five sides milling machine processing | |

Surface Treatment | High temperature spraying to prevent paint from falling off | |

Cutting thickness | within 70mm | |

Transmission mode | High wear-resistant wide square rail + imported high-precision ball screw | |

Driving mode | Key part: High precision servo control / Angle tilt large torque servo motor | |

Cutting motor | Special cutting motor waterproof and high temperature resistant | |

Cutting Motor | Special 15KW cutting motor, waterproof and high temperature resistant | |

Cutting Speed | 1-6000mm/min (according to thickness of stone ) | |

Control System | Shanghai Weihong | |

Programming mode | Modify data directly in operating system | |

Platform flap Angle | 0-85 degrees | |

Head rotation angel | 0-360 degrees | |

Head tilt angel | Any angel within 0 and 45 degrees | |

Tabletop | Hydraulic, thickened wooden table | |

Moving plates | Automatic moving plates | |

Tools setting | Automatic tools setting | |

Height measure | Automatic measuring the height of plates | |

Oil filling mode | Automatic oil injection and lubrication | |

Head motor Attached | 7.5KW stone-specific spindle | |

C-axis structure | Hollow reducer | |

Tools box | 1pcs saw blade, wrench, wearing parts | |

Dimensions | L 5600mm, W3400mm, H2600mm | |

Weight | 4000kg | |

Packaging | Film packaging (wrap film pearl cotton) | |

Machine Details :

Description | Photos |

Welding Heavy Work Bed

This machine is made of heavy materials, with a solid bed, which is durable and does not deform. The whole machine is processed by a large five-sided milling machine to process the guide rail surface and drill holes. |

|

Weihong Control System 1. Four-axis control system with movable handle, flexible point positioning, easy to learn and use, while ensuring equipment accuracy, high cost performance 2. The system is highly user-friendly, with extremely low educational requirements, and the machine can be operated by elementary school students. It can directly recognize CAD and can also directly modify the size according to customer requirements in the operating program for cutting and processing, without the need to use complex programs to generate CNC paths. |

|

Servo Motor and driver:VEICHI1500w

VEICHI machines use servo-driven motors, which provide smooth processing, low noise and low heat generation. |

|

Guide rail +ball screw High wear-resistant widened square Hiwin 30 guide rail + imported high-precision ball screw |

|

Milling Cutter and Tool Saw Blade Setting High-precision search for the origin of cutting tools is automated Prevents machining defects caused by thermal displacement and wear Reduces the preparation time for traditional trial cutting and manual measurement by 90%, reducing the burden on operators Avoids dangerous in-machine tool measurement |

|

Cutting Angle The machine head can swing 360 degrees at will, and can cut the board at any angle and any shape: horizontal cutting, vertical cutting, arc cutting, elliptical cutting, and circular cutting. The saw blade motor is added, and the machine head can automatically mill the cutter after being vertical, and can open the inner corner. It can cut large boards, perform 45-degree chamfer, open basin holes, stove holes, and cut oblique lines. Infrared positioning, precise cutting, and reduced waste generation |

|

Automatic sheet turning The platform can be turned 85 degrees, making loading and unloading of large heavy panels easy and labor-saving |

|

Automatic Board Moving No need to manually move the cut boards, saving time and effort Using a suction cup to move the plate is more convenient and labor-saving, and prevents overcutting. |

|

Hollow Reducer Large torque transmission capacity, high precision and reliability, with high transmission accuracy and stability. It can achieve safe and reliable transmission, reduce transmission error and vibration, and ensure smooth operation of the system. |

|

Laser positioning The laser positioning function is more accurate and standard, and improves the accuracy. |

|

Processing Technology Graphics :

Sample Picture :

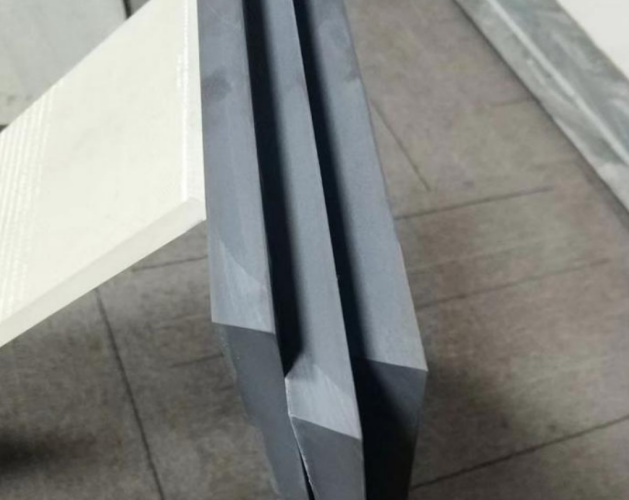

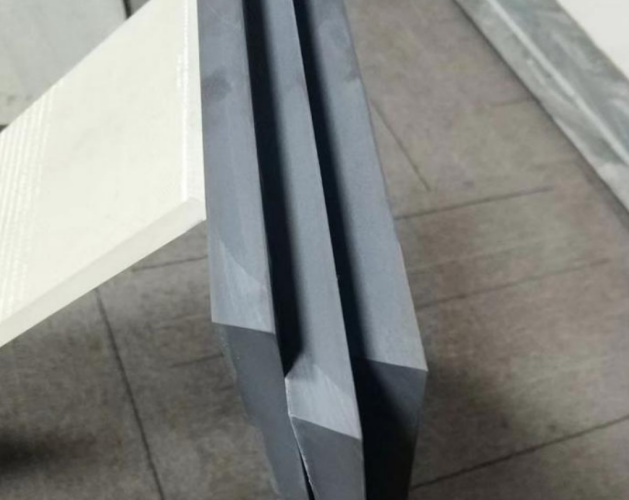

Horizontal and vertical cutting |    |

Cutting circle |

|

Cutting fan shape |

|

Cutting the Hole for the Wash Basin |

|

Drilling |

|

Engraving |

|

Company Introduction :

JCX CNC Machine Company, mainly engaged in the design, research, and production of CNC machines since 2010. Factory, over 8000M² workshops, with more than 80 working people, is located in Jinan city, Shangdong province.Focus on providing solutions for the cnc machine industry. We have our own machining workshop. All machines frame, gantry, and Z-axis are made in our own workshop. In this way, we can ensure our good quality and lower the cost.We can design and produce according to customers' requirements. (including machine structure, type, color, spare parts, and so on ).We can make OEM. ( with customers' own logo on the machine )

We have rich experience in exporting, and we will prepare well all customs documents and CO for making customs successfully.

4+1 Axis Bridge Cutting Machine

Machine Feature :

This machine is made of heavy materials, with a solid bed, which is durable and does not deform. The whole machine is processed by a large five-sided milling machine for guide rail surface and drilling. The key parts of the machine are imported high-quality accessories, with high processing precision, large production capacity and higher degree of automation. It adopts imported high-precision ball screw transmission, and the screw is highly heat-treated. The wear resistance is more durable and the service life of the whole machine is extended. This equipment has high-end configuration, the machine adopts servo control, fast running speed and stable operation. Intelligent and automated advantages:

1. The equipment adopts 15KW high-power special cutting motor, copper core coil, ultra-high power, low speed and high torque, high cutting force, and more labor-saving cutting. The machine adopts servo drive motor, stable processing, low noise and low heat. The cutting speed fluctuates up and down according to the hardness of the cutting material, processing speed and cutting depth.

2. The genuine four-axis control system with a movable handle is flexible for point positioning, easy to learn and use, while ensuring the accuracy of the equipment and high cost performance. The machine head can swing 360 degrees at will, and can cut the plate at any angle and any shape: horizontal cutting, vertical cutting, arc cutting, elliptical cutting, and circular cutting. The saw blade motor is added, and the machine head can automatically mill the cutter after being vertical, and can open the inner corner.

3. The system is highly user-friendly and has extremely low educational requirements. The machine can be operated at the elementary school level. It can directly recognize CAD and directly modify the size according to customer requirements in the operation program for cutting and processing, without using complex programs to produce CNC paths. The manufacturer provides free training on machine use.

4. Different from the three-axis stone cutting machine, this machine can not only cut and shape, but also cut large plates, perform 45-degree chamfers, open basin holes, stove holes, and cut oblique lines. Infrared positioning, precise cutting, and reduced waste generation.

5. The important electrical components in the control cabinet are all well-known brands, with strong impact resistance, anti-interference, moisture resistance and stability. The whole machine is resistant to strong electromagnetic interference, stable and reliable, ensuring long-term stable processing and operation of the equipment, and the chassis has a power-off protection function. The whole machine is waterproof to reduce water splashing, and the waterproof and dustproof structure effectively prevents dust or water from corroding the guide rails and screws, thereby increasing the life of the machine tool.

6. The new drag chain is used to separate the signal line and the power line according to the specifications, which can better prevent signal interference. The internal partition of the drag chain is fixed to prevent the cables from being twisted together during operation. The cable line adopts imported high-flexibility shielded wire, which has a longer service life.

7. The platform flips 85 degrees, and it is convenient and labor-saving to load and unload large heavy boards. The new five-axis saw has added functions, which does not require manual movement of the cut boards, and the tables of different customers can automatically optimize the layout, saving materials. One-time splicing and cutting. In short, the function upgrade has added the functions of automatic board movement and automatic optimization of layout.

8. The C-axis of the machine adopts a hollow subtraction machine, which has higher processing accuracy when used.

9. The attached machine head adopts a professional stone-specific spindle with a revolution of 24,000 and strong cutting force.

Application Industry :

1. Decoration industry : special-shaped lines and relief carvings on stone background walls;

2. Stone countertops for basin holes and European-style edging : suitable for artificial stone cabinets, quartz, granite, marble countertops and washbasins, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, rear arc water forming and polishing, etc.

3. 0 and 45-degree side cutting.

4. Drilling, grinding, trimming, carving, cutting, polishing and carving of other special-shaped stones, ceramics, glass, and ceramic stones.

Applicable Materials :

The stone bridge cutting machine is a popular product among kitchen and bathroom stone manufacturers. It is specially designed for cabinet artificial stone, quartz, granite, marble, tile, glass, wood, etc. It saves time and effort and is specially designed for kitchen and bathroom stone production.

Standard Requirements :

1. Mechanical safety standards, in line with national safety standards and national health regulations.

2. The equipment has good and comprehensive safety protection measures.

3. Movable parts that are frequently adjusted and maintained.

4. Electrical safety standards, the control system can ensure that there will be no danger when the equipment is powered off, and the equipment itself and personnel will not be harmed.

5. The electrical control system of the equipment has overload protection and short circuit protection functions

Technical Parameter :

Working size | Three-axis | 3200*2000*400mm |

C-axis | ±360° | |

A-axis | 0 and 45° | |

Saw Blade Diameter | 350mm-400mm | |

Bed frame | Seamless welding , Aging treatment, Five sides milling machine processing | |

Surface Treatment | High temperature spraying to prevent paint from falling off | |

Cutting thickness | within 70mm | |

Transmission mode | High wear-resistant wide square rail + imported high-precision ball screw | |

Driving mode | Key part: High precision servo control / Angle tilt large torque servo motor | |

Cutting motor | Special cutting motor waterproof and high temperature resistant | |

Cutting Motor | Special 15KW cutting motor, waterproof and high temperature resistant | |

Cutting Speed | 1-6000mm/min (according to thickness of stone ) | |

Control System | Shanghai Weihong | |

Programming mode | Modify data directly in operating system | |

Platform flap Angle | 0-85 degrees | |

Head rotation angel | 0-360 degrees | |

Head tilt angel | Any angel within 0 and 45 degrees | |

Tabletop | Hydraulic, thickened wooden table | |

Moving plates | Automatic moving plates | |

Tools setting | Automatic tools setting | |

Height measure | Automatic measuring the height of plates | |

Oil filling mode | Automatic oil injection and lubrication | |

Head motor Attached | 7.5KW stone-specific spindle | |

C-axis structure | Hollow reducer | |

Tools box | 1pcs saw blade, wrench, wearing parts | |

Dimensions | L 5600mm, W3400mm, H2600mm | |

Weight | 4000kg | |

Packaging | Film packaging (wrap film pearl cotton) | |

Machine Details :

Description | Photos |

Welding Heavy Work Bed

This machine is made of heavy materials, with a solid bed, which is durable and does not deform. The whole machine is processed by a large five-sided milling machine to process the guide rail surface and drill holes. |

|

Weihong Control System 1. Four-axis control system with movable handle, flexible point positioning, easy to learn and use, while ensuring equipment accuracy, high cost performance 2. The system is highly user-friendly, with extremely low educational requirements, and the machine can be operated by elementary school students. It can directly recognize CAD and can also directly modify the size according to customer requirements in the operating program for cutting and processing, without the need to use complex programs to generate CNC paths. |

|

Servo Motor and driver:VEICHI1500w

VEICHI machines use servo-driven motors, which provide smooth processing, low noise and low heat generation. |

|

Guide rail +ball screw High wear-resistant widened square Hiwin 30 guide rail + imported high-precision ball screw |

|

Milling Cutter and Tool Saw Blade Setting High-precision search for the origin of cutting tools is automated Prevents machining defects caused by thermal displacement and wear Reduces the preparation time for traditional trial cutting and manual measurement by 90%, reducing the burden on operators Avoids dangerous in-machine tool measurement |

|

Cutting Angle The machine head can swing 360 degrees at will, and can cut the board at any angle and any shape: horizontal cutting, vertical cutting, arc cutting, elliptical cutting, and circular cutting. The saw blade motor is added, and the machine head can automatically mill the cutter after being vertical, and can open the inner corner. It can cut large boards, perform 45-degree chamfer, open basin holes, stove holes, and cut oblique lines. Infrared positioning, precise cutting, and reduced waste generation |

|

Automatic sheet turning The platform can be turned 85 degrees, making loading and unloading of large heavy panels easy and labor-saving |

|

Automatic Board Moving No need to manually move the cut boards, saving time and effort Using a suction cup to move the plate is more convenient and labor-saving, and prevents overcutting. |

|

Hollow Reducer Large torque transmission capacity, high precision and reliability, with high transmission accuracy and stability. It can achieve safe and reliable transmission, reduce transmission error and vibration, and ensure smooth operation of the system. |

|

Laser positioning The laser positioning function is more accurate and standard, and improves the accuracy. |

|

Processing Technology Graphics :

Sample Picture :

Horizontal and vertical cutting |    |

Cutting circle |

|

Cutting fan shape |

|

Cutting the Hole for the Wash Basin |

|

Drilling |

|

Engraving |

|

Company Introduction :

JCX CNC Machine Company, mainly engaged in the design, research, and production of CNC machines since 2010. Factory, over 8000M² workshops, with more than 80 working people, is located in Jinan city, Shangdong province.Focus on providing solutions for the cnc machine industry. We have our own machining workshop. All machines frame, gantry, and Z-axis are made in our own workshop. In this way, we can ensure our good quality and lower the cost.We can design and produce according to customers' requirements. (including machine structure, type, color, spare parts, and so on ).We can make OEM. ( with customers' own logo on the machine )

We have rich experience in exporting, and we will prepare well all customs documents and CO for making customs successfully.